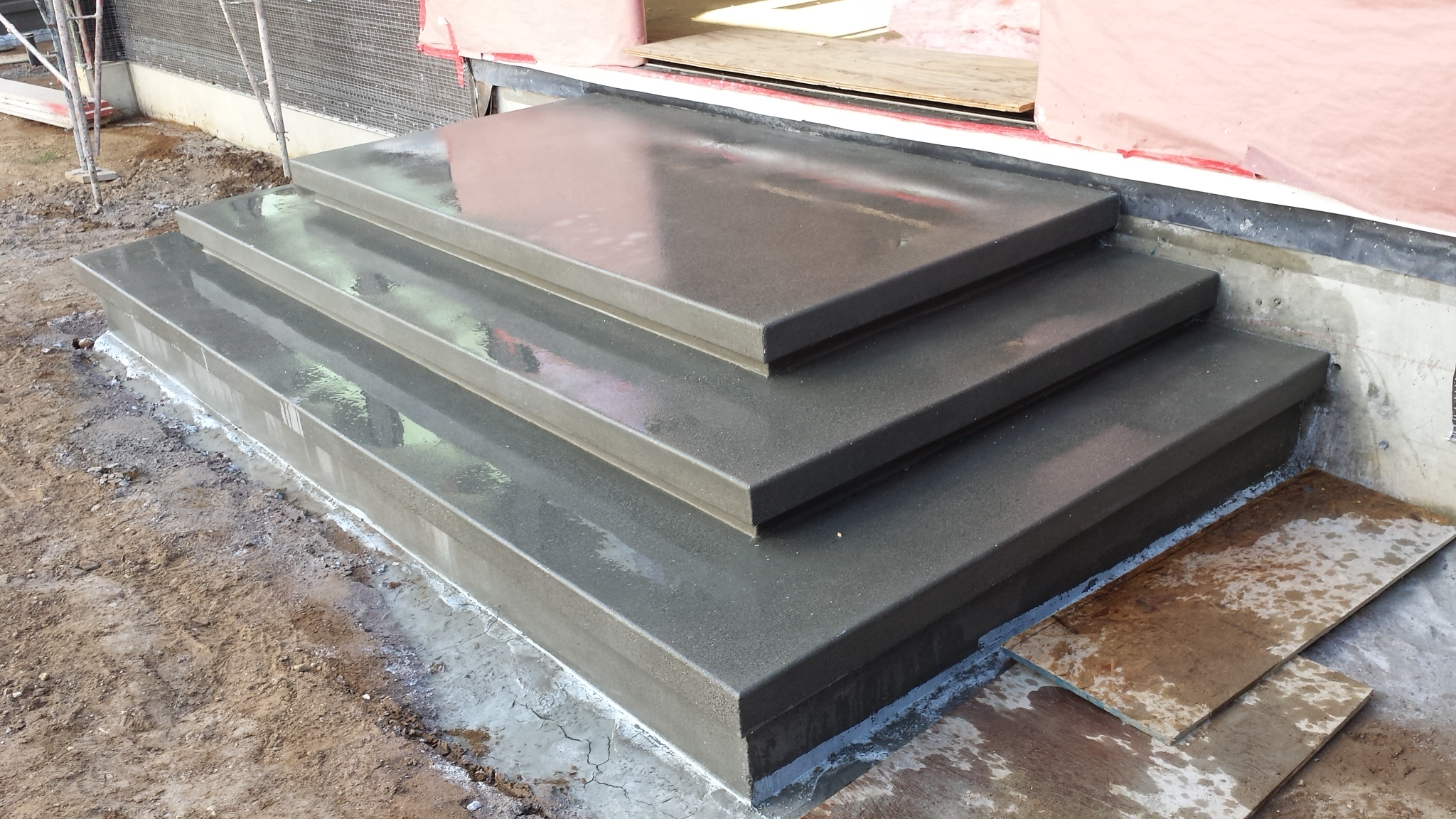

Several sets of stairs were just poured on Skyline Drive, getting ready for stucco. The concrete stairs were poured prior to the stucco to eliminate any guess work on the termination points of the stairs and stucco.

Stairs Formed-Form Liner not yet placed

These stairs will be cantilevered at the nosing. This detail gives a floating affect for each tread. There are several ways to achieve this detail. For these stairs, the contractor chose to use a form liner. The form liner is a piece of Styrofoam that can be nailed inside the form.

Form Liner in Place (Concrete also being placed)

When the concrete is poured into the form, the form liner holds back the concrete, creating the shape of the liner. After the concrete sets up, the forms are removed along with the liner, leaving the cantilevered stair nosing.

There are many finishes that can be applied to concrete: stamped, stained, etched, sand blasted, broomed, as well as others. For these stairs, we chose to use a product called Top-Cast. This product produces a surface that has the appearance of sandblasting or etching. It is available in many grades that produce a progressively deeper etch.

After the forms are removed and the concrete is given its final finish with a trowel, the Top-Cast is applied. The Top-Cast goes on in liquid form and is left on overnight. The next day, the Top-Cast is removed by power washing.

Top-Cast Applied

We chose the lightest grade available (#03). This will produce a finish similar to an acid etched finish. Why not just acid wash? or sand blast? Acid washing uses, well, a very caustic acid. This acid is not friendly to the environment. Many cities no longer allow this process. Sand blasting was also an option to produce this affect. The main problem with sandblasting is that it is very messy. It requires masking and careful application to avoid damaging anything in the vicinity of the steps.

Final Finish-Top-Cast #03

Stairs After Power Washing